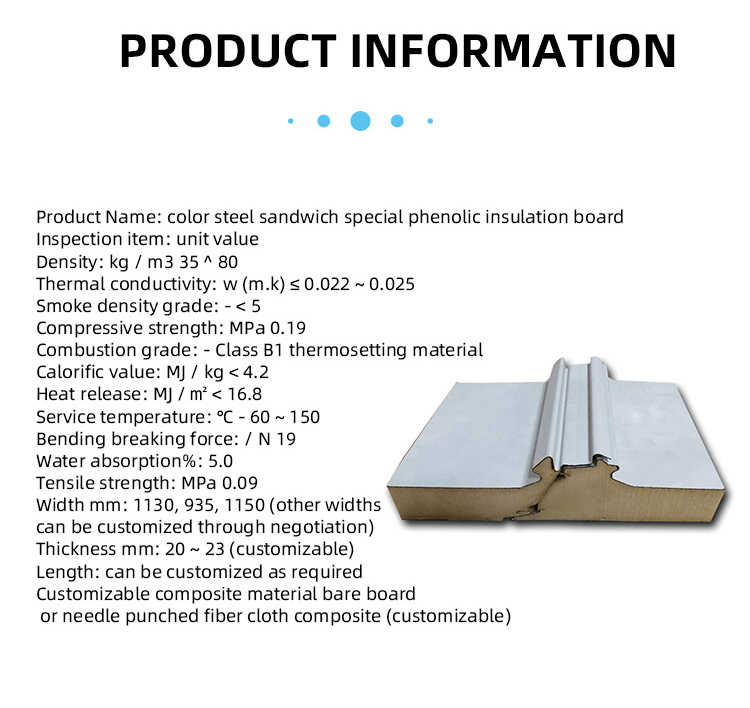

Light Steel Phenolic Sandwich Insulation Wall Board

Advantages of phenolic foam as insulation core material of color steel sandwich panel

Phenolic foam is a new and safe heat preservation and energy-saving material. Its performance and production technology have reached the world advanced level. In general, phenolic foam as the insulation core material of color steel sandwich panel has the following excellent characteristics compared with other insulation materials.

3.1 excellent fire resistance: organic thermal insulation materials such as polyurethane and polyphenylene will produce dense smoke and highly toxic after combustion, which is easy to cause death and increase the difficulty of fire extinguishing. The phenolic foam is nonflammable in case of fire. The combustion performance is up to class A, the maximum service temperature is 180 ℃ (allowable instantaneous temperature is 250 ℃), and the flame resistance of 100 mm thick phenolic foam can reach more than 1 hour without being penetrated. Under the direct action of the flame, there is carbon deposition, no dripping, no curling and no melting. After the flame combustion, a layer of “graphite foam” is formed on the surface, effectively protecting the foam structure in the layer.

3.2 excellent thermal insulation performance: low thermal conductivity (< 0.025w/m × K. It is more than twice as much as polyphenylene and is similar to polyurethane), which is an excellent material for heat preservation and insulation.