1、 Vacuum insulation board, thermal conductivity 0.008W/(m · K)

Vacuum insulation board, which is a high-efficiency insulation board made of inorganic fiber core material and high resistance gas composite film through vacuum packaging technology, and coated with specialized interface mortar.

The thermal conductivity of air is approximately 0.023W/(m · K), and to achieve a lower thermal conductivity than air, vacuum is the only solution. Its biggest advantage is that its insulation performance can surpass all other types of insulation materials, with excellent thermal conductivity index and fire resistance performance.. However, this board also has hidden dangers, such as difficulty in maintaining vacuum: if it is damaged, the insulation performance of the board will suddenly decrease; Secondly, the existing construction technology leads to too many board joints and too many thermal bridges, which poses a high risk of condensation; Furthermore, the smoothness of construction is also difficult to control, and the risk of detachment of the thin plaster system is also high.

2、 Aerogel thermal insulation material, thermal conductivity 0.02W/(m · K)

Aerogel material is called the lightest solid in the world. With nano silica aerogel as the main material, it is compounded by a special process. It has excellent properties such as high temperature resistance, low thermal conductivity, low density, high strength, green environmental protection, waterproof and incombustible. At the same time, it has excellent sound insulation and shock absorption performance. It is an indispensable efficient heat insulation material in metallurgy, chemical industry, national defense, aerospace and other fields.

This product combines thermal insulation and fire resistance, making it a rare material. However, even in Europe, this material has not been widely used in the field of construction engineering. On the one hand, the cost of this product is too expensive, and on the other hand, for the main components of the external insulation system that withstand cold and hot cycles, this product still needs to undergo more tests. Currently, there are no engineering cases in China to prove its reliability for external wall insulation.

3、 Foamed polyurethane, thermal conductivity 0.024W/(m · K)

The best performing single organic insulation material is polyurethane insulation material. According to the process, it is divided into on-site foam polyurethane and factory prefabricated hard foam polyurethane board. Field foaming polyurethane is a two-component hard foam material with thermal insulation and waterproof functions, which is made of isocyanate and polyol (combined polyether or polyurethane) as the main raw materials and added with additives.

On site foaming polyurethane has excellent integrity and waterproofing, making it very suitable for insulation and waterproofing of roofs and basement walls. It is applied to insulation in dry hanging curtain walls, making construction operations convenient and minimizing thermal bridging effects. Hard foam polyurethane board is a derivative product, but due to poor dimensional stability, there is not much difference compared to expanded polystyrene board.

4、 Domestic extruded polystyrene board, thermal conductivity 0.028~0.030W/(m · K)

Extruded polystyrene board is also a type of polystyrene board, but the production process is extrusion molding. Extruded polystyrene board, referred to as XPS board, is a rigid foam plastic product with closed cell structure made by heating extrusion molding with polystyrene resin or its copolymer as the main component and a small amount of additives.

Extruded polystyrene board is also a combination of waterproofing and insulation, with high stiffness, good compressive performance, and low thermal conductivity. It is very suitable for insulation inside roofs, floors, and basement walls. However, this type of board has poor breathability, poor dimensional stability, and poor adhesion with inorganic bonding mortar. It is commonly used for quality accidents such as system detachment and surface cracking in external wall insulation. Due to its low cost, this material has no greater advantage than expanded polystyrene board in the field of external insulation applications.

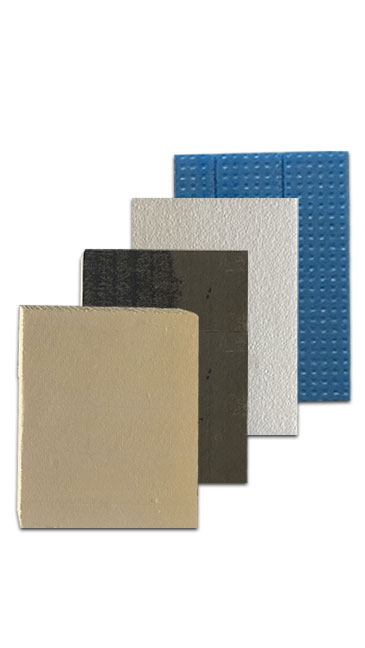

5、 Phenolic board, thermal conductivity 0.025W/(m · K)

Phenolic board is a closed cell phenolic foam board made by mixing phenolic resin with other additives such as curing agent, foaming agent, surfactant and filler. Phenolic board has good insulation performance, with a lower thermal conductivity than extruded polystyrene board. The sandwich insulation system in Japan extensively uses phenolic board.

The fire resistance of phenolic materials can be said to be innate,It is a closed-cell foam structure, which is equivalent to many small vacuums inside, blocking the spread of heat. It is possible not to burn or shrink in the face of open flames. Phenolic materials do not require the addition of any flame retardants, and have obvious price advantages compared with polyurethane materials of the same fire rating.

The flame spray burns the surface of the plate for five minutes, and there is no obvious feeling of heating up on the back of the plate, and the heat insulation performance is very good.In general, the thermal insulation effect of phenolic materials is similar to that of polyurethane, and it is also a lightweight foam material.Because the fire performance and comprehensive cost performance are higher than polyurethane, many fields with high requirements for fire protection and thermal insulation will choose phenolic materials.

Post time: Nov-20-2023