Products

-

Phenolic Foam Hard Board For External Wall

Recommended by Chinese phenolic insulation board manufacturers – Langfang Clear Company Langfang Clear Chemical Building Materials Co., Ltd. has been engaged in direct sales in the source factory, quality assurance, direct sales by manufacturers, selection of materials, and 17 years of dedicated and honest operation in the insulation material industry. Only by doing so can the quality of the source manufacturer be guaranteed. We only do a good job of phenolic insulation board products! Qualit... -

Phenolic Insulation Board Fire Resistant Wall Boards

Recommended by Chinese phenolic insulation board manufacturers – Langfang Clear Company Langfang Clear Chemical Building Materials Co., Ltd. has been engaged in direct sales in the source factory, quality assurance, direct sales by manufacturers, selection of materials, and 17 years of dedicated and honest operation in the insulation material industry. Only by doing so can the quality of the source manufacturer be guaranteed. We only do a good job of phenolic insulation board products! Qualit... -

Phenolic Decorative Exterior Wall Insulation Board

Thermal insulation decorative phenolic sandwich board that can be used for roof and wall insulation and decorative of building. Thermal insulation decorative phenolic sandwich board is used for the heat insulation of the building. The surface is compounded with calcium silicate, which is beautiful, waterproof, easy to clean, and can effectively resist the air corrosion. It can be used for years. Calcium silicate has more thermal insulation effect, which doubles the thermal insulation effect o... -

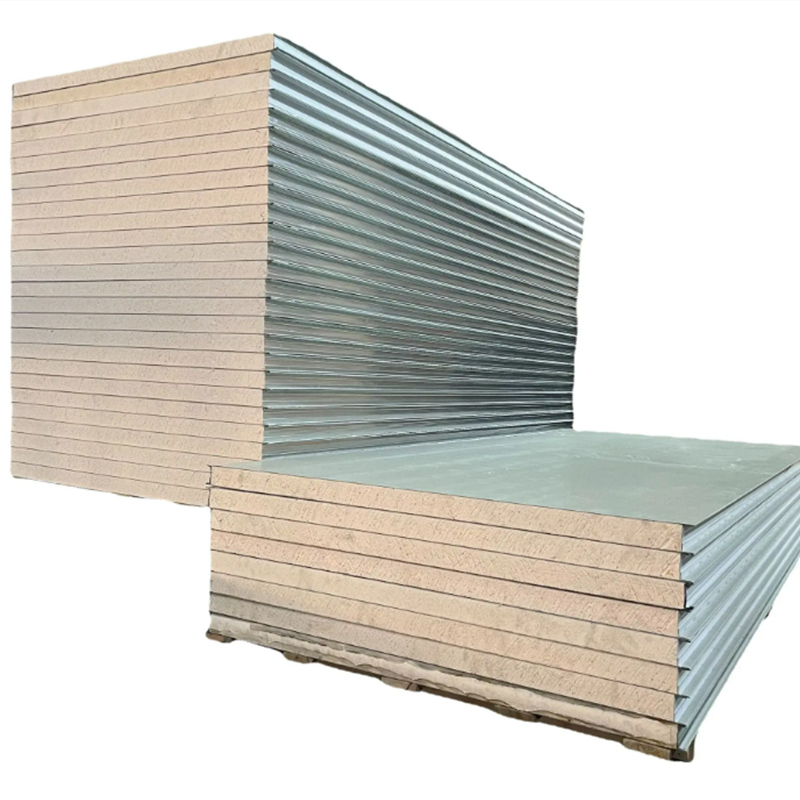

Phenolic Sandwich Panel For Clean Room Roof and Wall

Recommended by Chinese phenolic insulation board manufacturers – Langfang Clear Company Langfang Clear Chemical Building Materials Co., Ltd. has been engaged in direct sales in the source factory, quality assurance, direct sales by manufacturers, selection of materials, and 17 years of dedicated and honest operation in the insulation material industry. Only by doing so can the quality of the source manufacturer be guaranteed. We only do a good job of phenolic insulation board products! Qualit... -

Phenolic Insulation Pipe Tank Body Cold Insulation

Phenolic foam insulation pipe is a new type of pipe insulation material cut from phenolic foam module. The product has super insulation effect, fire resistance and flame retardancy, convenient construction and neat appearance. It has been widely used in pipeline insulation systems such as building cold and hot water pipes, building fire protection pipelines, building water supply and drainage pipelines, household heating and heating pipelines, oil transportation pipelines, liquefied natural g... -

Phenolic Composite Air Duct Foam Board

Phenolic air duct panel, phenolic foam hvac board, phenolic foam board for wind pipes. Phenolic foam board for air duct can produce different surface composite materials according to customer needs. Phenolic foam made of color steel and double-sided aluminum foil is beautiful, durable and solid.