PF phenolic board is a new type of environmentally friendly material that has advantages such as good insulation performance, high compressive strength, and good dimensional stability, and is deeply loved by various industries. Can be used for building exterior wall insulation, house wall decoration, cold storage refrigerated vehicles, airport runways, highways, etc.

We can understand the commonly used specifications of XPS extruded boards from the following aspects: flame retardancy, subsequent processing, edge structure, compressive strength, color, size, etc.

According to the flame retardancy of PF phenolic board, the flame retardancy level is B1 (flame retardant) level.

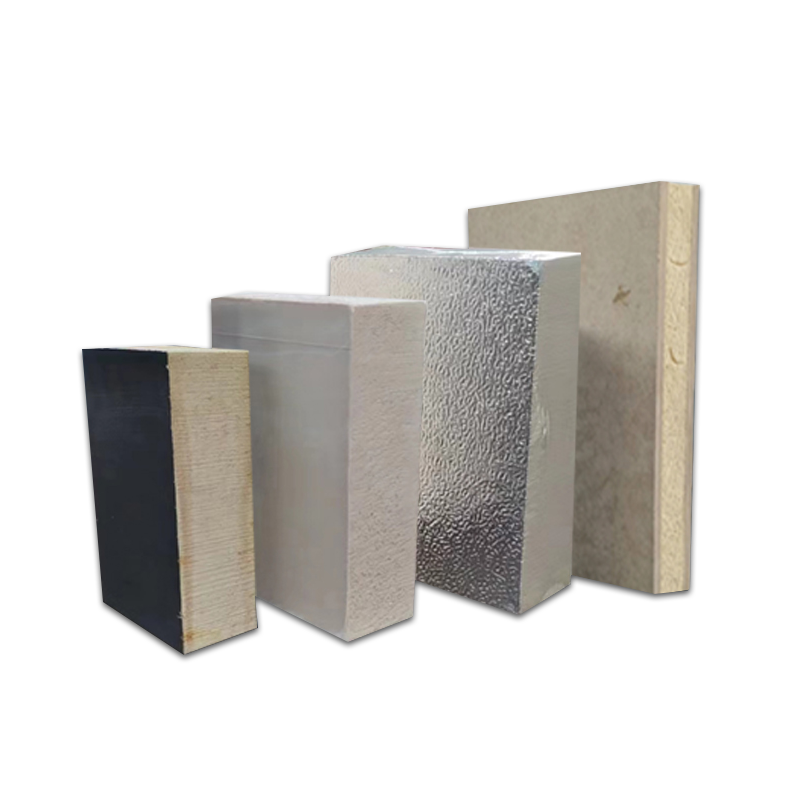

According to subsequent processing, it can be divided into: aluminum foil phenolic board, color steel phenolic sandwich board, ordinary phenolic board, mortar cement phenolic board, calcium silicate phenolic board, etc.

According to the edge structure of products, they are divided into: SS flat head products, SL products (lap joint), TG products (wedge groove), and RC products (rain groove);

The compressive strength of phenolic board can reach 150MPa.

Phenolic panels are generally yellow, white, and other colors, similar to our basic products that are generally white. Of course, different color masterbatches can be added according to customer requirements and processed into the desired color for customers.

The conventional dimensions of PF phenolic board are: 900mm * 600mm, 1200mm * 600mm, 2300mm * 1200mm, with a thickness range of 1cm-23cm, supporting special specifications for customization.

Post time: Jul-28-2023