Color steel sandwich panel is a structural panel with bearing capacity, which is composed of two layers of color coated steel plates as the surface layer, and materials with low strength and rigidity that can be insulated, such as hard foam plastic, rock wool board and other moisturizing materials as the core material, on a special automatic production line. Due to its structural characteristics, this type of panel is also known as a “sandwich panel.” It can be divided into roof panels, wall panels, partition panels, and ceiling panels according to the different parts of the building and panel types.

Color steel sandwich panel is a structural panel with bearing capacity, which is composed of two layers of color coated steel plates as the surface layer, and materials with low strength and rigidity that can be insulated, such as hard foam plastic, rock wool board and other moisturizing materials as the core material, on a special automatic production line. Due to its structural characteristics, this type of panel is also known as a “sandwich panel.” It can be divided into roof panels, wall panels, partition panels, and ceiling panels according to the different parts of the building and panel types.

As a multifunctional new type of building panel, color steel sandwich panels have the characteristics of excellent insulation, sound insulation, strong load-bearing capacity, bright color, flexible installation, low cost, waterproof, and seismic resistance. Since the 1980s, they have been widely used in large industrial factories, steel structure factories, activity rooms, clean workshops, building floors, temporary houses, warehouses, cold storage, sports halls, etc Supermarkets and places that require thermal insulation and fire prevention.

The color steel sandwich panel has a beautiful appearance, bright color, and good overall effect. It integrates load-bearing, insulation, fire prevention, and waterproofing, and does not require secondary decoration. It is fast and convenient to install, has a short construction period, and has good comprehensive benefits. It is a widely used and highly potential efficient building material.

The good performance of color steel sandwich panels not only depends on the optimal combination of panels and core materials, but more importantly, on the material of the core materials. However, currently, the commonly used insulation core materials for color steel sandwich panels have some drawbacks, most of which cannot simultaneously meet the characteristics of efficient fire insulation, high temperature resistance, and environmental friendliness; On the other hand, there are more and more manufacturers of this type of product, and the products produced are very similar, causing fierce market competition. Therefore, enterprises should adopt a new type of alternative insulation core material to catch up with the strong momentum of continuous updates and development in the field of color steel sandwich panels, improve product competitiveness, and achieve greater economic benefits.

The insulation, heat insulation, sound absorption and other properties of color steel sandwich panels mainly depend on their core material – insulation materials. This material not only needs good insulation, but also needs to have sufficient strength and stiffness, and also has good adhesion with color steel plates. Only in this way can the combined composite plate withstand the design load and meet the functional requirements of the building.

The new phenolic foam material (PF) has excellent performance in flame retardancy and toxicity. It has broad market prospects and huge economic potential, and will gradually replace other foam materials.

The new phenolic foam material (PF) has excellent performance in flame retardancy and toxicity. It has broad market prospects and huge economic potential, and will gradually replace other foam materials.

Introduction to phenolic foam

Phenolic foam insulation material is often referred to as phenolic foam. Phenolic foam is a kind of closed cell rigid foam made of phenolic resin, flame retardant, smoke suppressant, curing agent, foaming agent, and other additives through scientific formula. Phenolic foam has low thermal conductivity, light bulk density, non combustible, non-toxic, smoke-free, and lower water absorption than inorganic insulation materials such as glass wool and rock wool. At the same time, the mechanical strength is higher than other foamed plastics, and it has good processability and convenient construction. It has indisputable advantages in building insulation and wall insulation. It is the latest and best foam insulation material at present, known as the “king of insulation”.

In the 1980s, foreign scientists began to study phenolic resin and its products. Since the 1990s, phenolic composites, including phenolic foam, have been greatly developed. In recent years, the application of phenolic foam has been widely concerned and developed rapidly due to the strict requirements on the thermal stability and flame resistance of synthetic foams in high-rise buildings, transportation, ships, aviation, space technology and other aspects.

Advantages of phenolic foam as insulation core material of color steel sandwich panel

As a new type of safe heat preservation and energy saving material, the performance and production process of phenolic foam have reached the world’s advanced level. In general, phenolic foam, as the insulation core of color steel sandwich panel, has the following excellent characteristics compared with other insulation materials.

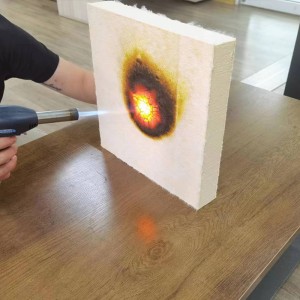

1) Excellent fire resistance: Organic insulation materials such as polyurethane and polystyrene can produce thick smoke and highly toxic substances after combustion, which can easily cause death and increase the difficulty of extinguishing fires. The phenolic foam will not burn in case of fire, and its combustion performance can reach Grade A at most. The maximum use temperature is 180 ℃ (250 ℃ is allowed instantaneously). The 100mm thick phenolic foam can resist the flame for more than 1 hour without being penetrated. Under the direct action of the flame, there is carbon deposition, no dripping, no curling, no melting. After the flame burns, a layer of “graphite foam” is formed on the surface, effectively protecting the foam structure in the layer.

2) Excellent insulation performance: low thermal conductivity (0.024W/m.k), more than twice that of polystyrene, similar to polyurethane, making it an excellent material for insulation and insulation;

3) Corrosion resistance and aging resistance: It can resist almost all inorganic acids, organic acids and organic solvents. Long term exposure to sunlight without obvious aging phenomenon, thus possessing good aging resistance;

4) Low density and light weight: the density of phenolic foam material is below 80kg/m3, which can reach about 50kg/m3. It can reduce the self weight of buildings, reduce the load on buildings, reduce structural costs, and construction is simple and fast, which can improve work efficiency

5) Sound absorption performance: phenolic foam has excellent sound absorption performance, and the open cell foam structure is more conducive to sound absorption;

6) Environmental protection: Rock wool and glass wool are harmful to the environment and people. When polyurethane and polystyrene are burned and heated, they will decompose into highly toxic gases such as hydrogen cyanide and carbon monoxide. The phenolic foam adopts fluorine free foaming technology and has no fiber, which meets the national and international environmental requirements.

7) Service life: The service life of polystyrene board and polyurethane is generally about 10 years, and the weather resistance is relatively poor. The phenolic foam does not shrink and deform, and the service life can be up to 30 years. It is a rare building insulation material.

Post time: Oct-23-2023