Characteristics of phenolic insulation board

Phenolic insulation board is a new type of green and environmentally friendly material, with a long-term use temperature of -190 ℃~150 ℃. It does not ignite when exposed to fire, and does not melt droplets, soften, and only carbonize the surface in high temperature environments. The thermal conductivity of phenolic insulation board is only about 0.022W/m.k, and its insulation performance is very good. Its most prominent features are flame retardant, low smoke, and resistance to high-temperature decomposition. It can be used for on-site foaming or mechanical processing, and can be made into plates, shells, and various special-shaped products. It overcomes the shortcomings of the original foamed plastic insulation materials, such as flammability, smoke and deformation in case of heat, and retains the characteristics of the original foamed plastic insulation materials, such as light weight and convenient construction. Phenolic board has a rich source of raw materials, low prices, and simple production and processing, resulting in a wide range of product uses. It is suitable for large cold storage, storage tanks, ships, various insulated pipelines, and the construction industry. If used in factories, mines, and mechanical equipment with strict fire protection requirements, its characteristics of flame retardancy, low smoke, and high temperature resistance can be more prominent. For example, insulation of ships, warships, trains, armored vehicles, as well as papermaking, chemicals, pharmaceuticals, and other aspects.

Performance comparison of various insulation materials for phenolic insulation board:

Performance comparison of various insulation materials for phenolic insulation board:

1. Defects of polyurethane: It is easy to burn and produce toxic gases when exposed to fire, posing a threat to human health.

2. Defects of polystyrene: It is easy to burn when exposed to fire, and will shrink after prolonged use, resulting in poor insulation performance.

3. Defects of rock wool and glass wool: harmful to the environment, breeding bacteria, high water absorption, poor insulation effect, poor strength, and short service life.

4. Advantages of phenolic resin: non combustible, low thermal conductivity, good insulation effect, sound insulation, good weather resistance, and a service life of over 30 years.

5. It has uniform closed cell structure, low thermal conductivity and good thermal insulation performance, which is equivalent to polyurethane and superior to polystyrene foam;

6. The applicable temperature range is wide, which can be used at -200 ℃~200 ℃ in the short term and -190 ℃~150 ℃ for the long term, superior to polystyrene foam (80 ℃) and polyurethane foam (110 ℃);

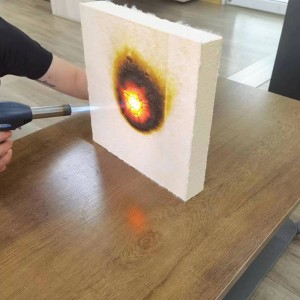

7. Phenolic molecules only contain carbon, hydrogen, and oxygen atoms. When subjected to high-temperature decomposition, apart from producing a small amount of CO gas, no other toxic gases will be produced, with a maximum smoke density of 5.0%. The 25mm thick phenolic foam plate can only be slightly carbonized on the surface but can not burn through after being subjected to 1500 ℃ flame spraying for 10min, neither can it ignite nor emit thick smoke and toxic gas.

8. The phenolic foam composite board is resistant to almost all inorganic acids, organic acids and organic solvents, except that it may be corroded by strong alkali. Long term exposure to sunlight without obvious aging phenomenon, therefore it has good aging resistance.

9. The cost of phenolic foam is low, which is only two thirds of that of polyurethane foam.

Post time: Aug-14-2023