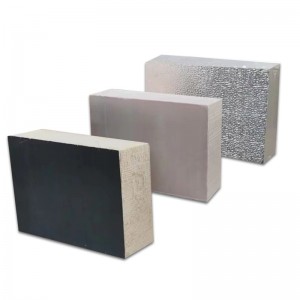

Phenolic insulation board is made of phenolic foam, which is mainly composed of phenol and formaldehyde. Phenolic foam is a new type of fire-resistant, fireproof and low smoke insulation material (under limited conditions). It is a closed cell rigid foam plastic made of phenolic resin added with foaming agent, curing agent and other additives.

characteristic

Its most prominent features are non combustible, low smoke, and resistance to high-temperature decomposition. It overcomes the shortcomings of the original foamed plastic insulation material, such as flammability, smoke and deformation in case of heat, and retains the characteristics of the original foamed plastic insulation material, such as light weight and convenient construction.

1) Excellent fire resistance

The insulation layer is made of phenolic foam, which is compounded with other materials for building insulation. It can basically reach the national fire protection standard B1. The possibility of external insulation fire is fundamentally eliminated. The temperature range is -190 ℃~+150 ℃.

2) Outstanding insulation and energy-saving effects

Phenolic insulation board has good insulation performance, with a thermal conductivity of about 0.022W/(m · k), which is far lower than the commonly used inorganic and organic exterior wall insulation products in the market, and can achieve higher energy-saving effects.

3) Lightweight and non absorbent

Phenolic insulation board has a light weight and a unit weight of generally 30-80Kg/m ³。 At the same time, phenolic insulation boards do not absorb water and are not afraid of rain.

4) Safety and environmental protection

Phenolic insulation board is an environmentally friendly and green product that does not irritate the skin or cause any harm to the human body. When burned, it releases non-toxic smoke (under limited conditions, formaldehyde, carbon monoxide, etc. are released beyond the combustion limit).

5) Good dimensional stability

Phenolic insulation board has excellent dimensional stability and will not experience shrinkage, deformation, and other situations no matter what environment it is in.

6) Widely used

Phenolic insulation board can not only be used for external insulation systems of building exterior walls, but also for activity rooms, purification workshops, cold storage color steel sandwich panels, air conditioning ducts, pipeline insulation, curtain wall insulation, roof insulation, machine room cabinet insulation, equipment insulation, carbon crystal electric heating board insulation, and various fields that require insulation.

application

The thermal conductivity of phenolic foam is about 0.023 (about 1/2 of polyphenylene, and the thermal conductivity of polyphenylene board is about 0.042), the fire rating is noncombustible A (can withstand 150 ℃ high temperature), and the price is similar to that of polyurethane. Polystyrene foam and polyurethane foam are both flammable and not resistant to high temperature. Their use is restricted by the fire department. Phenolic fire-resistant insulation board can effectively solve the problem of building fire insulation. Phenolic insulation board does not melt or soften at high temperatures, has low smoke generation, does not diffuse flames, is resistant to flame penetration, has excellent fire resistance, and has good insulation and energy-saving effects. It combines excellent fire resistance and good energy-saving effects, and is suitable for external wall insulation. Application form of phenolic insulation board:

1) External insulation of building exterior walls (thin plastering system, integrated insulation and decoration, curtain wall system)

2) Central air conditioning composite duct insulation (steel faced phenolic composite duct, double-sided aluminum foil phenolic composite duct)

3) Color steel sandwich panel field (activity room, purification engineering, clean workshop, cold storage, cabinet room, etc.)

4) Roof insulation (residential roofs, factory roofs, roof insulation bricks)

5) Low temperature and deep cold pipeline insulation (LNG pipeline, liquefied natural gas pipeline, cold and hot water pipeline)

6) Other fields that require insulation and insulation

Since the 1990s, phenolic foam materials have been greatly developed. First, they were valued by the British and American military and used in aerospace, defense and military industries. Later, they were used in places with strict fire protection requirements such as civil aircraft, ships, stations, oil wells, and gradually pushed to high-rise buildings, hospitals, sports facilities and other fields.

Post time: Aug-25-2023