What materials are used for the partition walls of steel structure factory buildings, and the advantage of wall panels as prefabricated components of the enclosure structure is the main condition for improving comfort. At present, the types of steel structure walls are divided into the following:

Firstly, block walls were initially the most common partition wall material, and this type of panel is mainly used for the internal and external walls of steel structure factory buildings. This type of block wall installation is not convenient and requires piecemeal splicing, which is labor-intensive and time-consuming.

The second most commonly used is the light steel keel wall, which cannot achieve sound insulation effect during installation. It requires filling both sides of the keel with soundproofing cotton and cement fiber board materials, which greatly increases the construction time and labor force. Another type of panel is ALC sand aerated concrete wall panel. The disadvantage of this type of wall panel is that it is not resistant to hanging force, and the hanging force cannot meet the requirements.

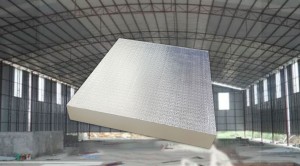

Finally, there is a new building material, Phenolic lightweight partition board, which is made of phenolic insulation foam board, and the outer panel is aluminum foil or color steel plate. This kind of plate is closed cell foam waterproof, moisture-proof and heat insulation, and has fire resistance. The fire resistance rating is B1. The specification of this kind of plate can be customized. A solid plate is in the middle of the whole plate, which is resistant to hanging, good construction and cost saving.

The comprehensive performance of phenolic foam insulation board is relatively high.

Post time: Jun-26-2023