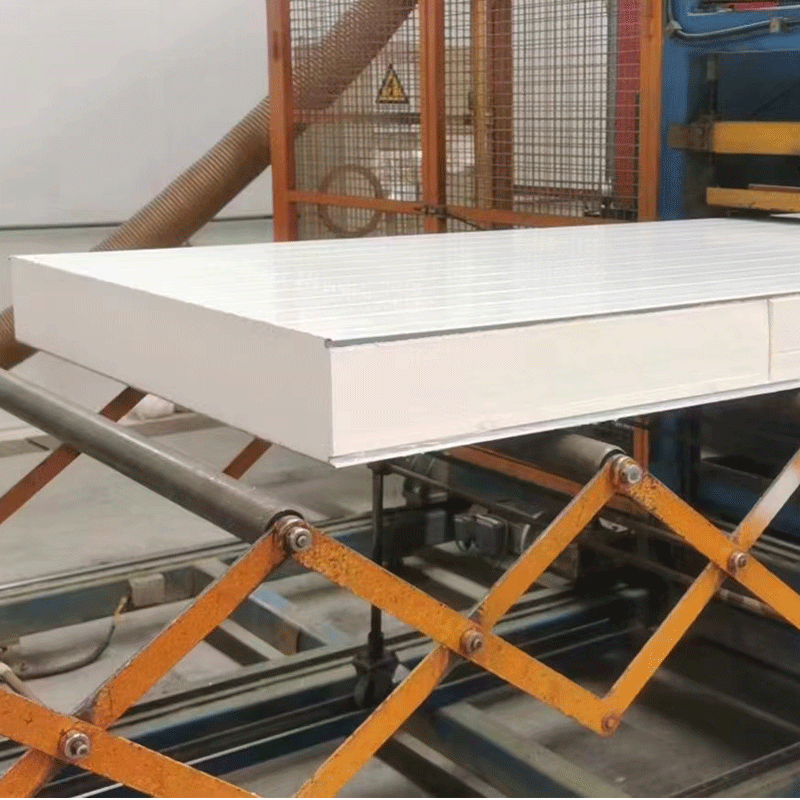

Extruded board, polystyrene board, polyurethane board, and phenolic board are commonly used insulation materials for color steel sandwich panels on the market.

The price of extruded board and polystyrene board will be cheaper than that of polyurethane board and phenolic board, but the thermal insulation and fire resistance are lower than those of polyurethane board and phenolic board.

The price of extruded board and polystyrene board will be cheaper than that of polyurethane board and phenolic board, but the thermal insulation and fire resistance are lower than those of polyurethane board and phenolic board.

In terms of thermal insulation effect, polyurethane board and phenolic board are equivalent. The R value of 10cm thick board at room temperature is 5, and the thermal conductivity is about 0.025. However, for the polyurethane board and phenolic board with the same fire protection grade of B1, the polyurethane board needs to be added with a large amount of flame retardant, and the price will be relatively higher. The fire resistance of phenolic is derived from genes.Because it is hard foam, its structure is stable, and it will not deform at high temperature and low temperature, which will not affect normal use.

The extruded board will contract when exposed to fire, and it will also produce a pungent odor.

Polystyrene board also contracts when exposed to fire and produces a pungent odor. And there are dripping objects. Polyurethane boards also contract when exposed to fire, producing a pungent odor accompanied by a large amount of smoke. Phenolic board is flame sprayed, non combustible, high-temperature carbonized, non shrinkage, no dripping, low smoke density, and environmentally safe.

Polystyrene board also contracts when exposed to fire and produces a pungent odor. And there are dripping objects. Polyurethane boards also contract when exposed to fire, producing a pungent odor accompanied by a large amount of smoke. Phenolic board is flame sprayed, non combustible, high-temperature carbonized, non shrinkage, no dripping, low smoke density, and environmentally safe.

From the above, it can be seen that the comprehensive performance and cost-effectiveness of phenolic panels are relatively high.

Post time: May-15-2023