Cold storage insulation materials meet the following conditions:

The thermal conductivity is relatively low, so using a thinner insulation layer can achieve better insulation effect. Low density and affordable. Good moisture resistance and frost resistance, sturdy and sturdy, with high compressive strength and durability, to ensure good fire resistance for long-term use, without self ignition or combustion support, in order to improve the fire resistance performance of cold storage. It does not produce any odors, absorb odors, or emit toxic substances, which is of great significance for food storage in cold storage. Cold storage insulation materials should only have good corrosion resistance, do not breed moths or other bacteria, and are easy to install, construct, and disassemble.

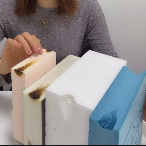

Polyurethane foam has low thermal conductivity, low water absorption, high compression strength and high durability; However, material prices are relatively high;

Polyurethane foam has low thermal conductivity, low water absorption, high compression strength and high durability; However, material prices are relatively high;

Polystyrene foam plastic (EPS) is light in weight, good in heat insulation, low temperature resistance, acid and alkali resistance, and has certain elasticity. Products can be cut; However, it is easier to absorb water when used in cold storage, which affects the insulation effect. Therefore, moisture-proof and waterproof measures need to be taken during use;

Extruded polystyrene foam (XPS) has high compressive strength and moderate price;

Phenolic foam has low thermal conductivity, low water absorption, high durability, light weight, good thermal insulation and low temperature resistance. It does not burn in case of fire, and does not melt or shrink. Because no flame retardant is needed, the price is saved.

Post time: Jul-26-2023