New Delivery for Air Duct Panel - Phenolic Pipe Phenolic Foam Hvac Board Phenolic Foam Board For Wind Pipes – Clear

New Delivery for Air Duct Panel - Phenolic Pipe Phenolic Foam Hvac Board Phenolic Foam Board For Wind Pipes – Clear Detail:

Product Parameters

Specifications

| Parameters of phenolic board | numerical value |

| density(kg/m3) | 30~80(Customizable) |

| Thermal conductivity(W(M)) | 0.020~0.029 |

| Smoke density grade(%) | 6 |

| compressive strength(Kpa) | ≥150 |

| Combustion grade | Thermosetting fireproof non combustible material |

| calorific value(MJ/kg) | ≤4.2 |

| Heat release(MJ/m2) | ≤16.8 |

| working temperature(°C) | -140×160 |

| Bending fracture force(/N) | 34 |

| Water absorption(%) | <7 |

| size(MM) | Customizable |

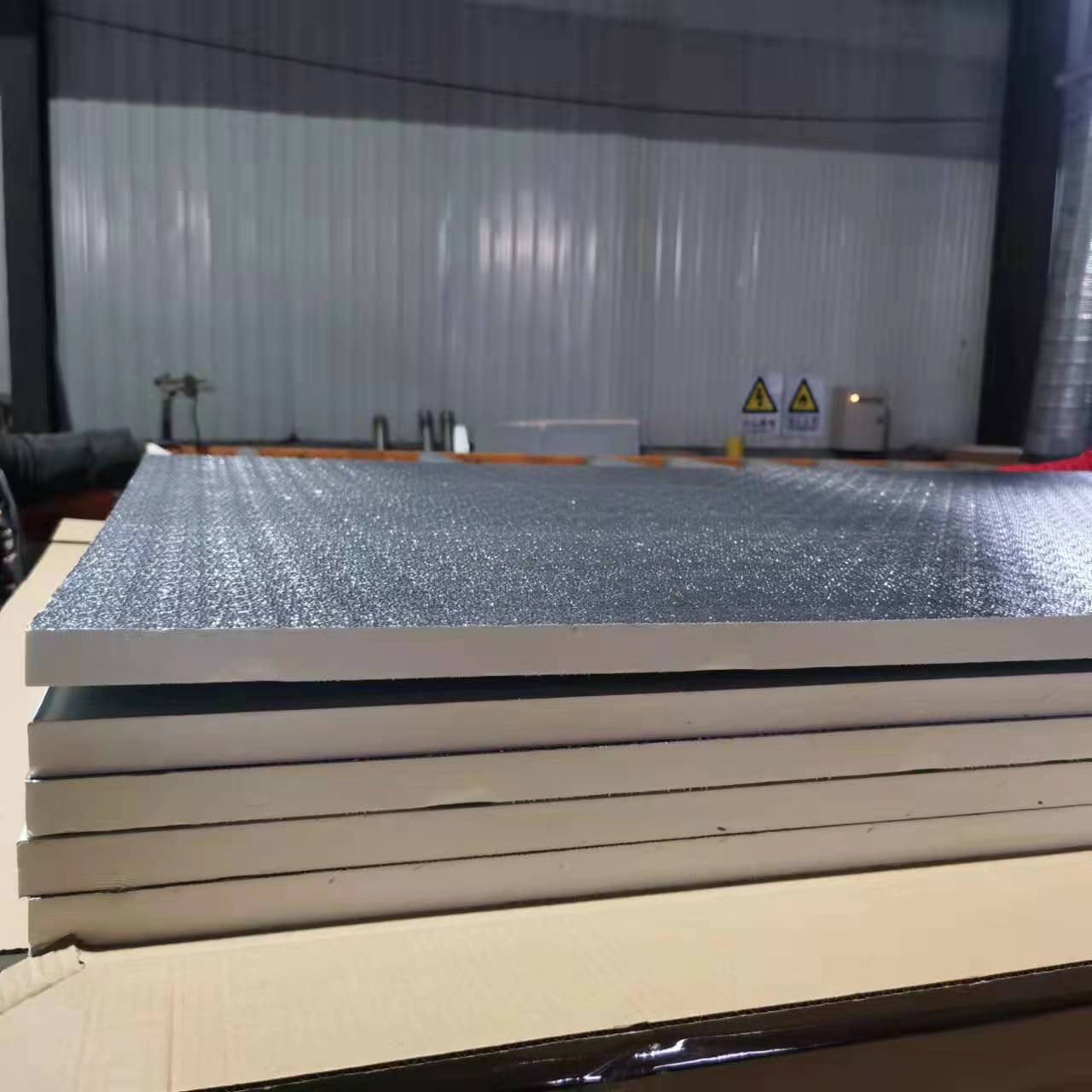

| Production process | Two sided fireproof aluminum foil facing, phenolic foam insulation sandwich |

Product advantages

The middle layer of phenolic composite air duct is phenolic foam, and the inner and outer layers are made of embossed aluminum foil. Composite air duct is the most widely used, among which rubber plastic composite air duct, phenolic, glass magnesium, etc. are the main representatives. Composite air duct is a kind of rubber plastic composite air duct system made of rubber plastic composite insulation material, which can completely replace the traditional air duct, air valve, air outlet, static pressure box and insulation material in the air supply system of air conditioning.

Phenolic resin is the earliest industrialized plastic product in the world, and phenolic foam is just developed. Phenolic foam plastic is known as the “king of heat preservation”. It was used in the heat preservation of missiles and rocket heads in the early stage. It has become the fastest developing variety of plastics in the United States, Britain, Japan and other developed countries. Phenolic foam material has good flame retardancy, low thermal conductivity, excellent sound absorption performance and long service life. Phenolic foam materials are widely used in all aspects of the national economy because of their superior characteristics, such as central air-conditioning air ducts, cold and heat transmission pipes, clean plants, shopping malls, light body fast loading rooms, cold storages, refrigerated vehicles, aircraft, ships, hotels and entertainment compartments, etc. where fire-proof, light-weight, heat preservation, sound insulation, clean and moisture-proof materials are required.

Phenolic foam plate and aluminum foil are compounded into sandwich plate, and then special flange fittings are added. The phenolic composite air duct is used for central air conditioning ventilation. The internal and external surfaces of phenolic composite sandwich panel are coated aluminum foil, and the intermediate layer is phenolic foam material. Its comprehensive performance has been greatly improved, especially in mechanical properties, such as bending resistance, compression resistance, brittleness and processing performance. It basically meets the requirements of air conditioning ventilation pipes.

Performance advantage editing

Stocking & Packing

Usually cartons or pallets or as customized

Application scenario

Service advantages

Langfang Clear chemical building materials Co., Ltd. was established in 2007. Phenolic composite air duct plate is one of the core industries of the company. It provides customized service for drawings, OEM and ODM processing service, self owned brand sales service, one-stop procurement service for air duct plate and related auxiliary materials and ventilation materials, and builds a multi-level and wide field service system to strive to provide customers with efficient and high-quality services.

Keliyi has more than 15 years of experience in the production of phenolic foam thermal insulation materials, a professional R & D team, continuous innovation to meet the market demand, 11 production lines with large capacity and stable supply, and products sell well all over the world. Keliyi, which is constantly developing, is willing to join hands with the vast number of business friends and share the innovation achievements.

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. Quality is our life. Customer need is our God for New Delivery for Air Duct Panel - Phenolic Pipe Phenolic Foam Hvac Board Phenolic Foam Board For Wind Pipes – Clear , The product will supply to all over the world, such as: panama, UK, Brasilia, Our company abides by the management idea of "keep innovation, pursue excellence". On the basis of assuring the advantages of existing products, we continuously strengthen and extend product development. Our company insists on innovation to promote the sustainable development of enterprise, and make us become the domestic high-quality suppliers.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!