High Quality for Duct Insulation - Phenolic Foam Insulation Board For Wall And Roof Insulation – Clear

High Quality for Duct Insulation - Phenolic Foam Insulation Board For Wall And Roof Insulation – Clear Detail:

Product Parameters

| 1 |

Conventional thickness |

20mm~230mm |

| 2 |

Length x width(mm) |

Customizable |

| 3 |

Fire rating |

Nonflammable B1 class |

| 4 |

Density of core material |

40~80kg/m³ |

| 5 |

Water absorption |

≤3.7% |

| 6 |

Thermal conductivity |

0.020-0.025W/(mk) |

| 7 |

Heat resistance |

-60℃–+150ºC |

| 8 |

Wind resistance strength |

≤1500Pa |

| 9 |

Compression strength |

≥0.18Mpa |

| 10 |

Bending strength |

≥1.1Pa |

| 11 |

Leakage air volume |

≤1.2% |

| 12 |

Thermal resistance |

0.86m2 K/W |

| 13 |

Smoke density |

No toxic gas release |

| 14 |

Dimension stability |

≤2%(70±2ºC,48h) |

| 15 |

Oxygen index |

≥45 |

| 16 |

Duration of the resistance |

>1.5h |

| 17 |

Formaldehyde Emission |

≤0.5Mg/L |

| 18 |

Air flow max |

15M/s |

| 19 |

Stress and deformation |

Qualified

|

| 20 |

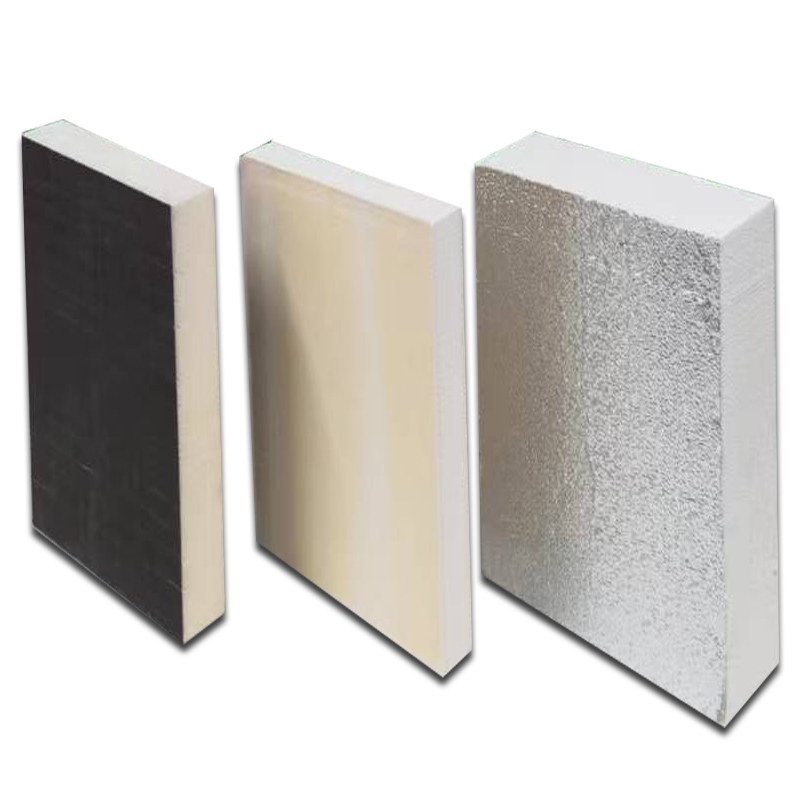

Surface composite |

Double sided color steel, single-sided color steel, double-sided aluminum foil |

Product advantages

Phenolic foam thermal insulation board can be used for thermal insulation of internal and external walls and roofs. It has the advantages of fire prevention, thermal insulation, sound insulation, light weight, beauty and hygiene

Fire protection and thermal insulation:

Good strength:

Material comparison:

Advantages of phenolic foam insulation materials

| Material Science | weight(Kg/m³) | thermal conductivityW/(m·℃) | Thermal resistance value(0.025㎡×℃/W) | Combustion grade |

| Phenolic | 40~80 | 0.025 | 1 | Flame retardant B1 |

| polyurethane | 20~40 | 0.025 | 1 | Flame retardant B2 |

| Eps | 20~40 | 0.030 | 0.86 | Flame retardant B2 |

| Xps | 20~40 | 0.041 | 0.61 | Flame retardant B2 |

| Rock wool | 80~120 | 0.053 | 0.48 | Non combustible A |

| Glass wool | 80~120 | 0.036 | 0.69 | Non combustible A |

| Foam glass | 80~120 | 0.066 | 0.066 | Non combustible A |

In terms of its thermophysical properties, PIR phenolic foam boards are significantly higher than those of alternative

thermal insulation products.

Stocking & Packing

Usually cartons or pallets or as customized

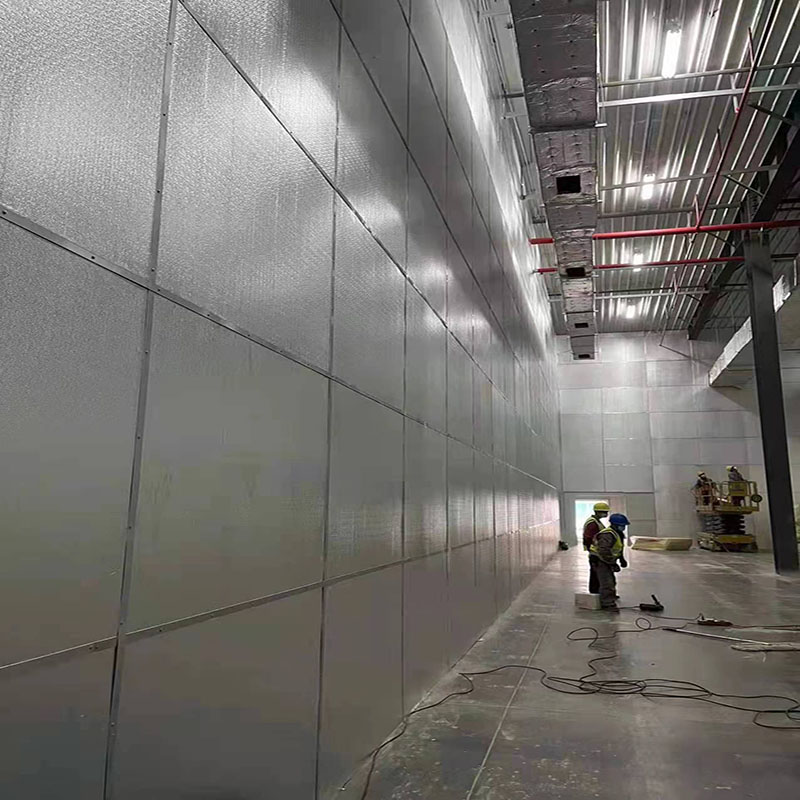

Application scenario

Service advantages

Langfang Clear chemical building materials Co., Ltd. was established in 2007. Since its establishment, it has always adhered to the business philosophy of scientific innovation and integrity based. The company strives to achieve product quality and reputation in the industry.

Our company focuses on the research and production of phenolic foam insulation products, constantly improves the technical indicators of phenolic panels, and takes scientific innovation as the driving force for enterprise development. Constantly adapt to market changes and develop new products. The products are widely used in the fields of wall insulation, central air conditioning ventilation, industrial pipeline, storage tank insulation, steel structure ceiling insulation and wall panel sandwich in factories, factories, workshops, farms and so on.

While improving product performance, improve the management system and improve product service efficiency. Clear company provides OEM and ODM processing and customization services, and its own brand market development services to meet customer needs in all aspects.

Constantly strengthen product guarantee measures. In 2016, the company completed the phenolic panel inspection and testing room, which makes the testing of phenolic panels routine and daily. Establish a three-tier responsibility mechanism for phenolic board, and check the production, testing and sales at three levels, with responsibility assigned to each person. Ensure that the ex factory products are qualified.

The company’s phenolic board has passed the ISO2001 international quality system certification; The phenolic board system structure of the National Fire Department has passed the fire prevention acceptance.

The company will continue to focus on the R & D and production of phenolic products in the future to serve the building energy-saving market. Our company is willing to sincerely cooperate with new and old customers, work together for win-win, and seek broader development; All staff of Keli will serve you wholeheartedly. Welcome friends from all sides to negotiate and consult.

Product detail pictures:

Related Product Guide:

Our organization promises all customers with the first-class products and solutions and the most satisfying post-sale service. We warmly welcome our regular and new clients to join us for High Quality for Duct Insulation - Phenolic Foam Insulation Board For Wall And Roof Insulation – Clear , The product will supply to all over the world, such as: Uruguay, Finland, Cyprus, We accomplish this by exporting our wigs directly from our own factory to you. The goal of our company is to get customers who enjoy coming back to their business. We sincerely hope to cooperate with you in the near future. If there's any opportunity, welcome to visit our factory!!!

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!