Phenolic board is a common insulation material, and its quality directly affects its insulation performance and service life. Here are some methods to distinguish between good and bad phenolic boards:

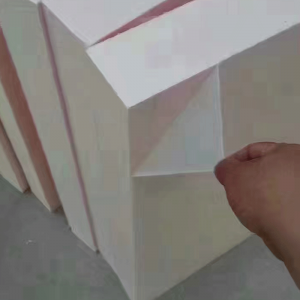

Observation of appearance: The surface of a good phenolic board is flat, without obvious defects such as bumps, cracks, bubbles, color differences, etc., and the color is uniform and clear; Sharp edges, clear edges, smooth cutting, and no burrs. Poor quality phenolic boards may have color differences, blurriness, and uneven surfaces, which can easily lead to quality issues during use.

Check material: the main raw material of phenolic board is phenolic foam, while phenolic foam is made of phenolic resin, flame retardant, smoke suppressant, curing agent, foaming agent, and other additives. Therefore, the quality of phenolic boards can be distinguished by observing their material. High quality phenolic foam should be used as raw material for high-quality phenolic board, while poor quality phenolic board should be made of inferior materials.

Testing performance: The performance indicators of phenolic panels include density, thermal conductivity, compressive strength, etc. These indicators can be tested using professional testing equipment and compared with national standards to determine the quality of phenolic boards.

Understanding the production process: The production process of phenolic boards also has a significant impact on their quality. Assembly line board and mold board are two common production processes, among which mold board generally has the phenomenon of slag dropping. The factory can be required to composite grid cloth mortar or interface agent to not only overcome powder shedding, but also effectively improve bonding strength and reduce water absorption. Therefore, understanding the production process helps to determine the quality of phenolic boards.

Observing the effectiveness of use: In actual use, the quality of phenolic boards can be judged by observing their performance. A good phenolic board should have good insulation performance, longer service life, and lower maintenance costs. If any problems arise, they should be promptly addressed and replaced with inferior quality phenolic boards.

In summary, when selecting phenolic panels, the above factors should be comprehensively considered, and high-quality products produced by reputable manufacturers should be selected to ensure their insulation performance and service life.

Post time: Mar-20-2024